P474 – HV sputter deposition system ESRF

Application

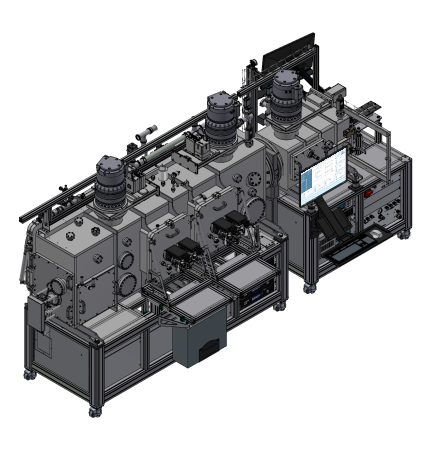

HV inline sputter deposition system for thin film and multilayer deposition at special sized substrates for X-Ray mirror production

Year of delivery

2021

Installation site

ESRF, Grenoble, France

Design Features

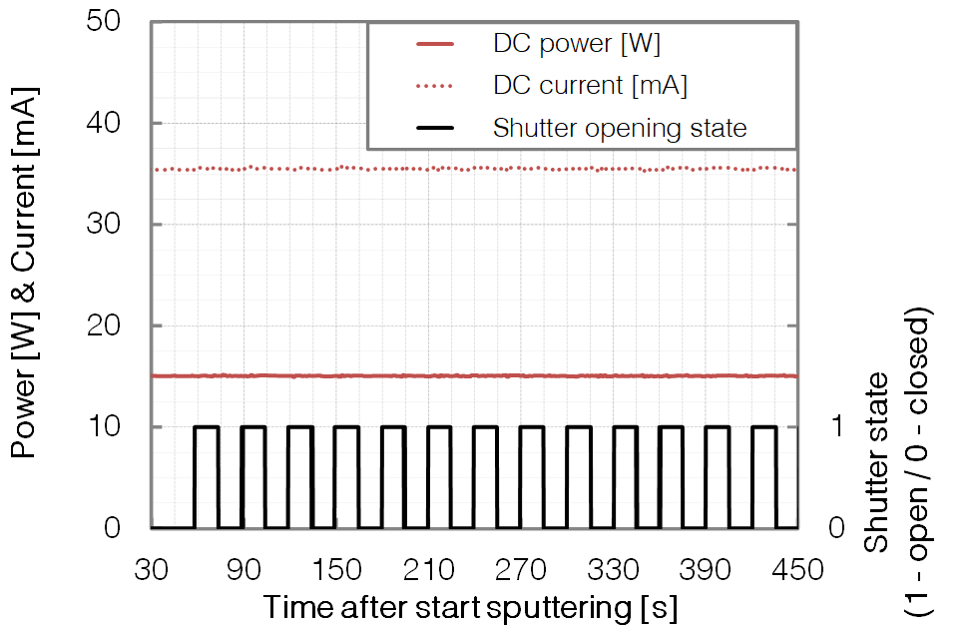

- Inline HV magnetron sputter deposition system with full automatic control system for x-ray mirror production with very high film uniformity below 1%.

- Four 3″ magnetrons in face to face configuration.

- Two magnetrons mounted at a differentially pumped fliping door for fast and easy target exchange and source cleaning.

- Direct gas inlet close to the target installed at each magnetron.

- Low pressure and low power sputtering possible.

- In situ adjustable target to substrate distance by manual motion of the source.

- Stepper motor driven source shutter.

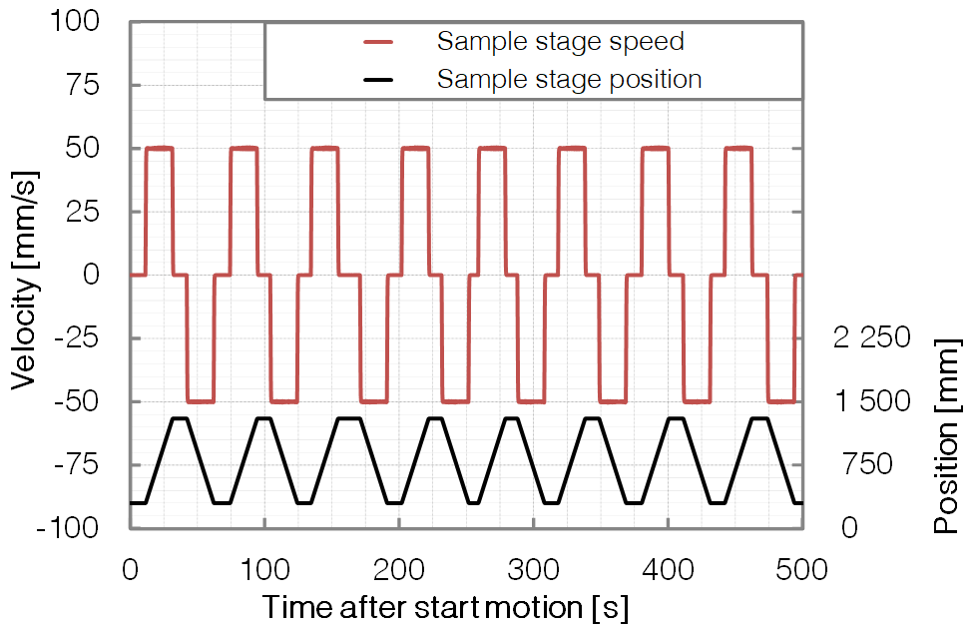

- Motorized sample trolley with speed profile motion mode as well as constant speed motion mode implemented.

- Maximal sample size of 300mm x 80mm x 80 mm.

- Integrated bake out system.

- Load lock chamber with manual sample transfer system and sliding access door and lamp heating option.

Special Features

- Large motion speed range from about 1 mm/s up to 200mm/s possible.

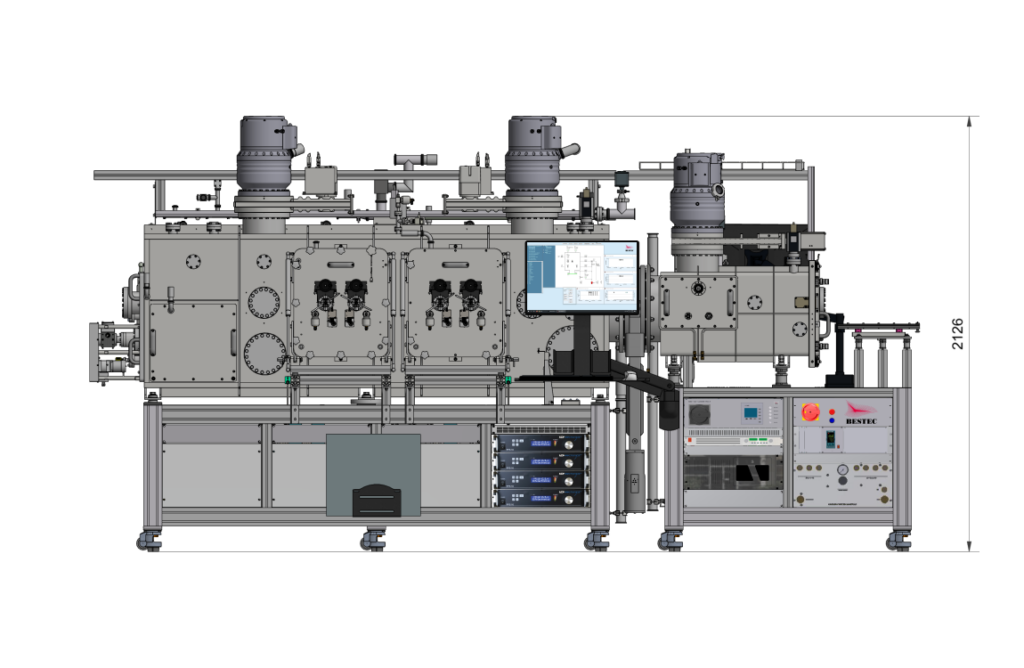

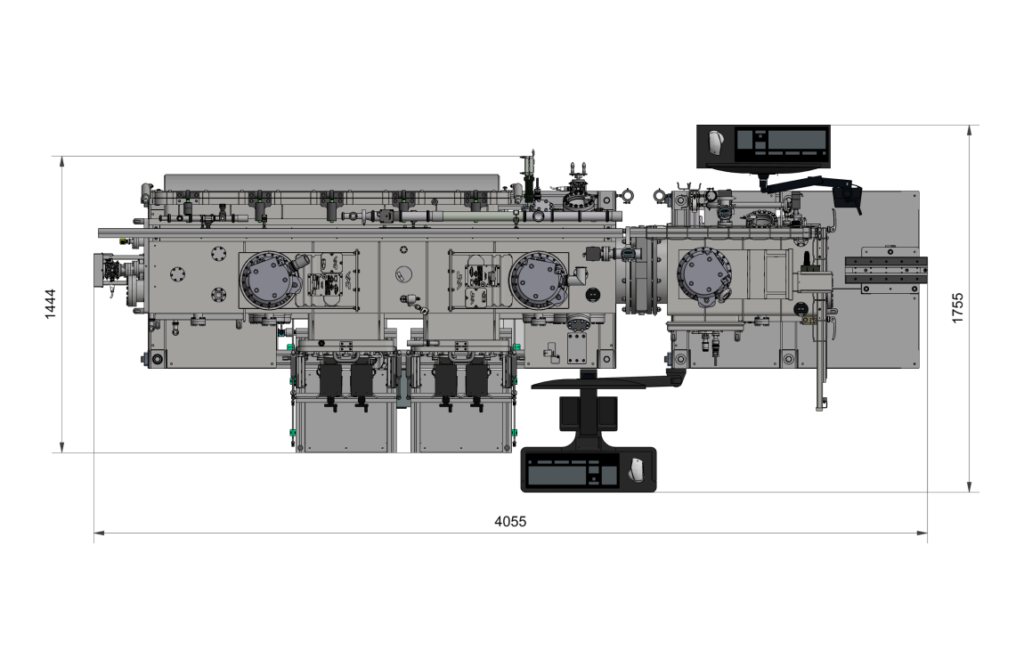

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

Cubic shape chamber, about 2320 mm length, about 435 mm width & about 700 mm height

Material

stainless steel

Load lock chamber

Size

Cubic shape chamber, about 820 mm length, about 360 mm width & about 370 mm height

Material

stainless steel

Vacuum

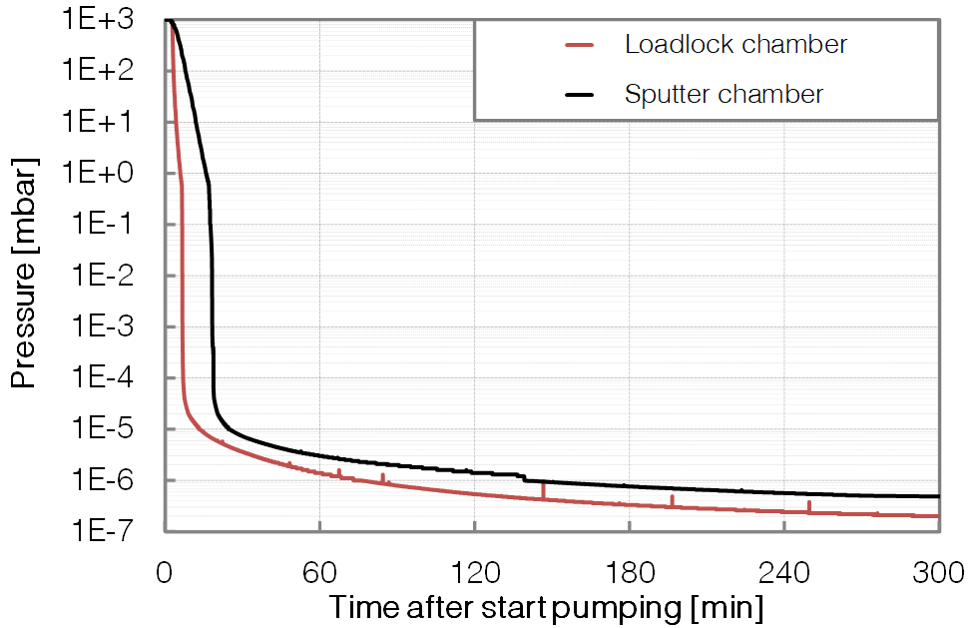

Sputtering chamber

Base pressure

< 2 * 10-8 mbar

Pump down time

0,5 hours to < 10-7 mbar

Chamber pumping

Turbo pumping stage, several chamber doors differentially pumped by dry foreline pump

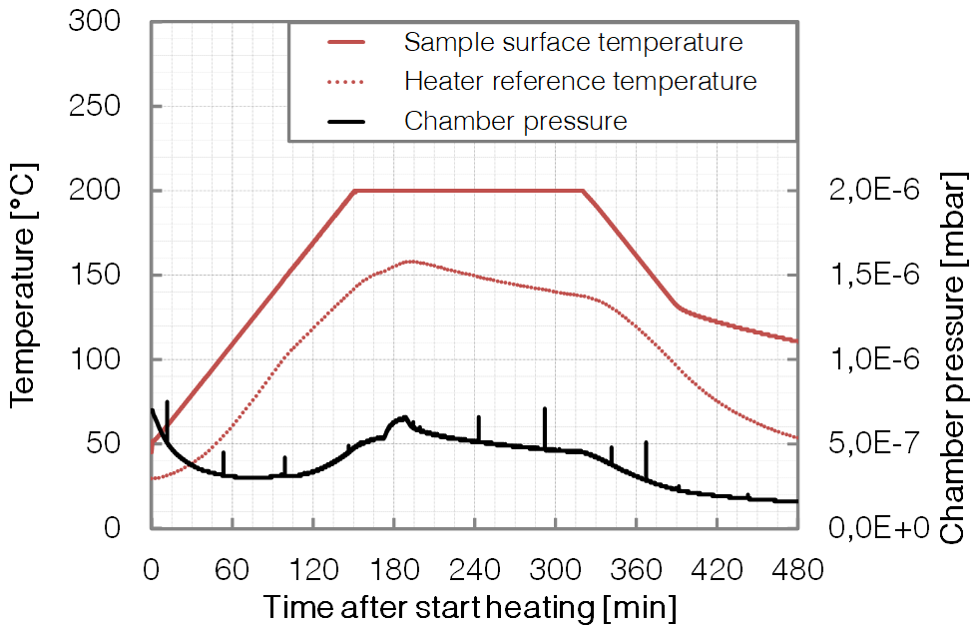

Bake out

< 150°C

Load lock chamber

Base pressure

< 5 * 10-8 mbar

Pump down time

3,5 hours to < 3 * 10-7 mbar

Chamber pumping

Turbo pumping stage, chamber door differentially pumped by dry foreline pump

Manipulator features

Sputtering chamber

Sample size

max. 300mm x 80mm x 80 mm special shaped samples

Motion axes

Motorized sample translation axis with motion speed range of min. 1 mm/s up to max. 100 mm/s, incl. speed profile feature

Sample preparation features

Load lock chamber

Thermal treatment

max. 200°C at sample (with temperature regulation)