P311+318 – 4″ HV/UHV Multitech. deposition system PDI

Application

Multi chamber system as combination of HV e-beam deposition system & UHV sputter deposition system for thin film and multilayer deposition at 4″ substrates

Year of delivery

2011

Installation site

PDI, Berlin, Germany

Design Features

- Multitechnique deposition system consting a HV E-beam deposition system and a UHV magnetron sputter deposition system connected to a load lock chamber.

- HV E-beam system with combination of two thermal evaporation sources and one multi pocket e-beam source.

- Multi pocket rotary crucible e-beam source (8 pockets with 4ccm each).

- Two thermal evaporation source for standard 3″ and 4″ boat heaters.

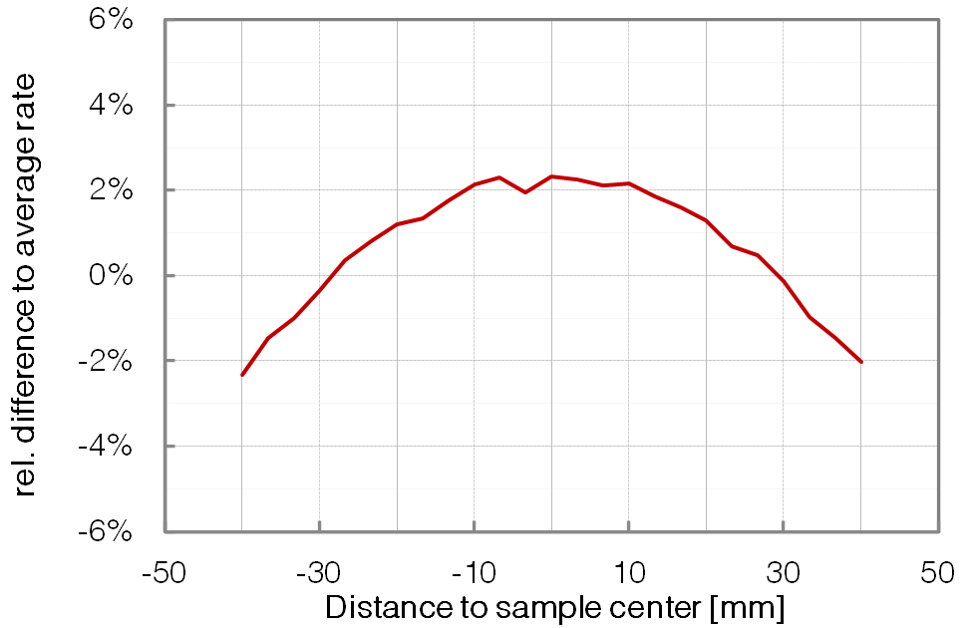

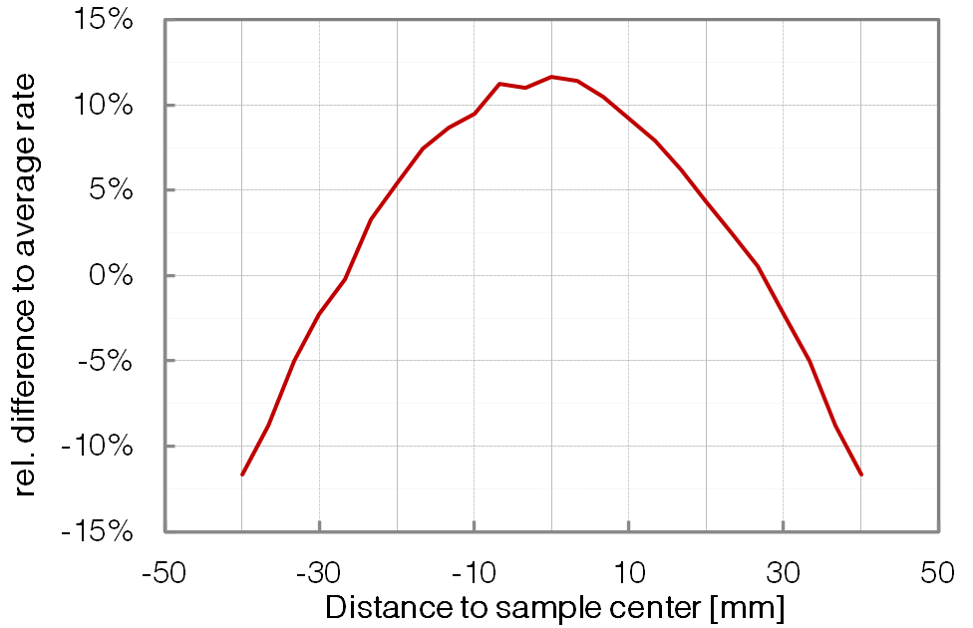

- Deposition uniformity better than 2% over 3″ diameter.

- Manually tiltable sample manipulator with integrated sample cooling (without temperature regulation).

- Thickness sensor installed (for rate control and deposition thickness end point detection).

- UHV sputter system with face to face sputtering and sample preparation by ion gun.

- Three 6″ magnetrons installed.

- Deposition uniformity better than 2% over 3″ diameter.

- Three thickness sensors installed (one at each magnetron deposition position for rate control).

- Griddless ion source for sample precleaning and mild etching

- Fully motorized 2 axes sample manipulator (manipulator arm rotation, manipulator z translation) with integrated Bias potential option and sample temperature above 600°C.

- Variable source to sample distance by manipulator z translation.

- Load lock chamber with lamp heating stage.

- Integrated bake out system.

Special Features

- Glace angle depostion possible at e-beam system.

- Reactive deposition possible in both sub-systems.

- Gasflow control via manual dosing valve at e-beam system.

- Gasflow control via MFC at sputtering system.

- Different sample sizes (1″ wafer to 4″ wafer) can be handled (using different clamp connection points of the sample holder).

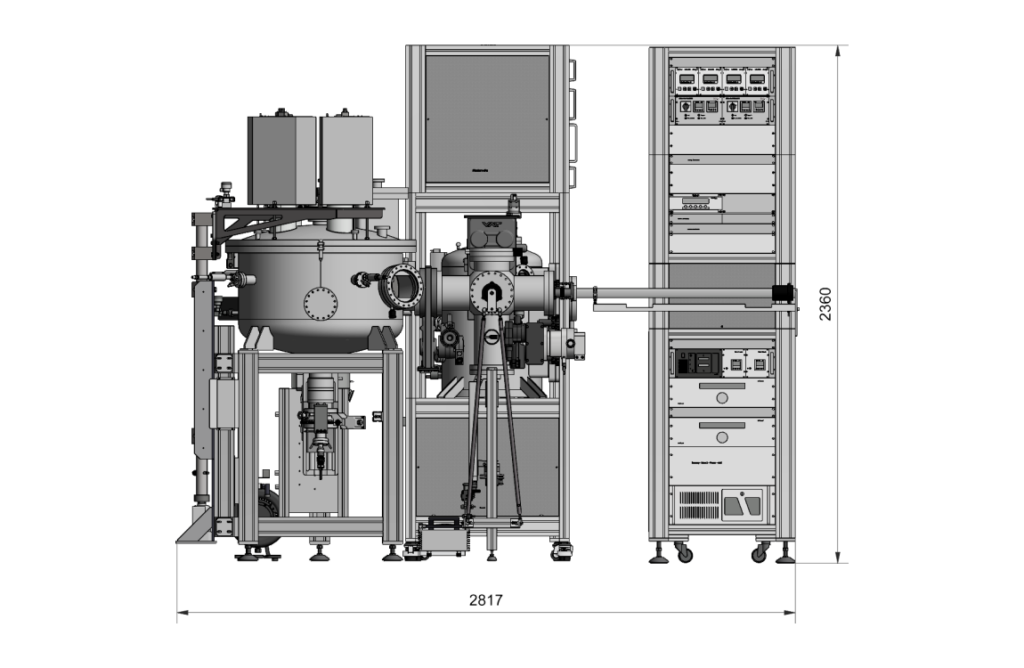

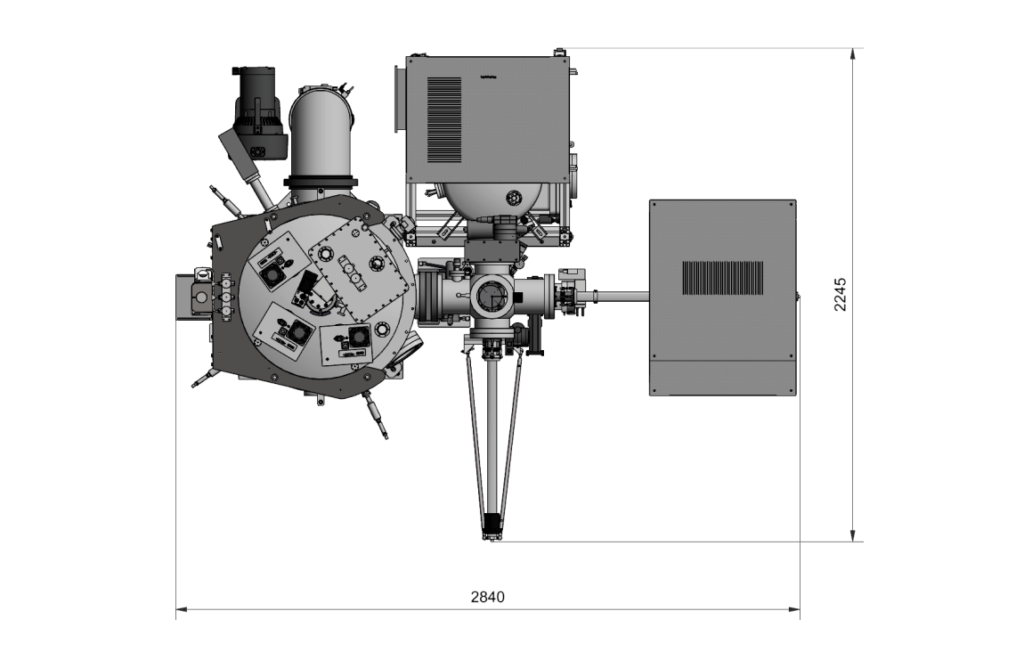

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

About 740 mm diameter, about 780 mm height

Material

stainless steel

E-beam chamber

Size

About 450 mm diameter, about 720 mm height

Material

stainless steel

Load lock chamber

Size

About 150 mm diameter, about 520 mm height

Material

stainless steel

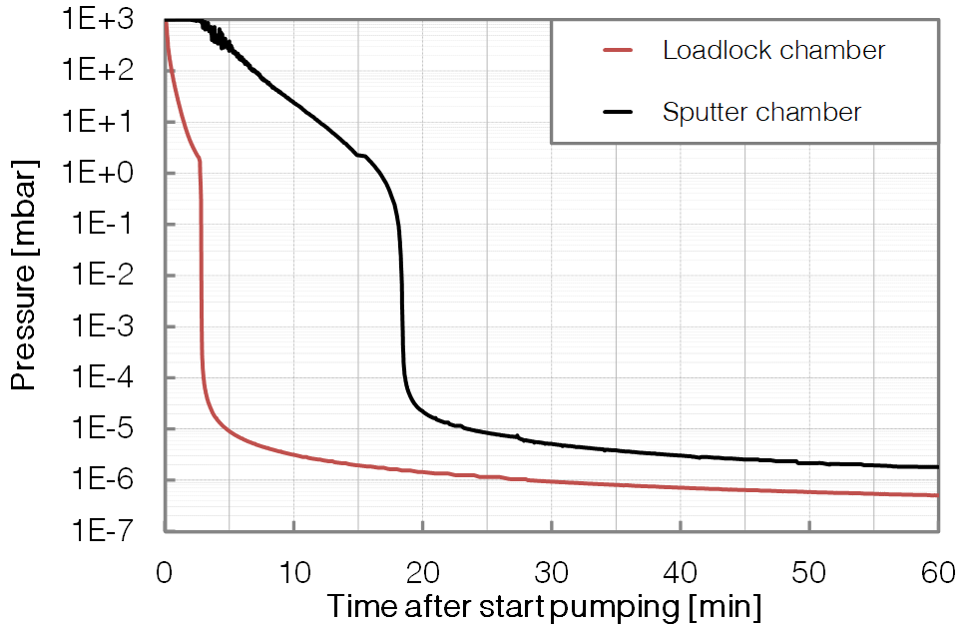

Vacuum

Sputtering chamber

Base pressure

< 3 * 10-9 mbar

Pump down time

1 hour to < 2 * 10-6 mbar

Chamber pumping

Turbo pumping stage, chamber lid differentially pumped by dry foreline pump

Bake out

< 150°C

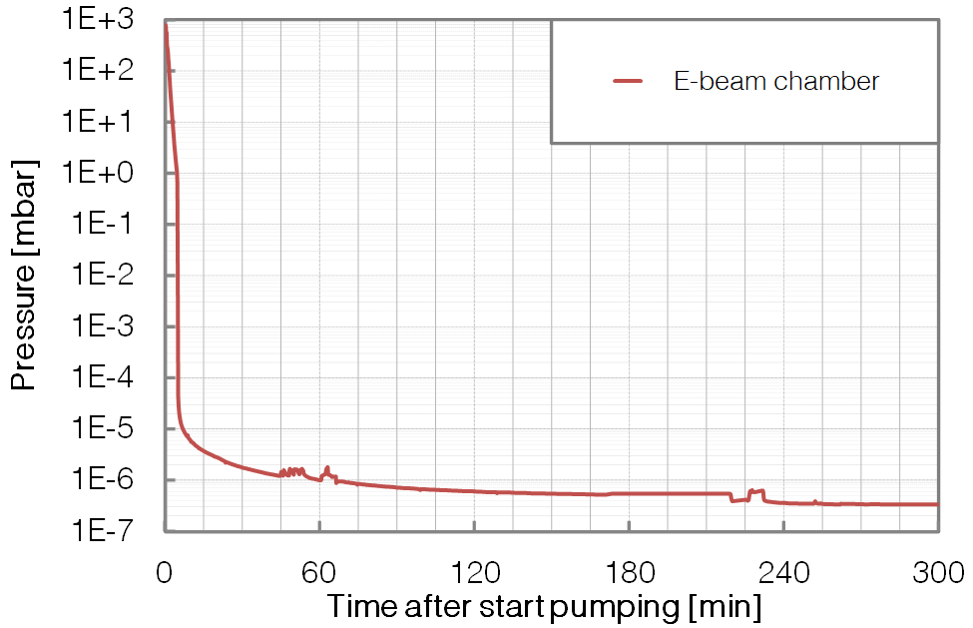

E-beam chamber

Base pressure

< 5 * 10-7 mbar

Pump down time

1 hour to < 10-6 mbar

Chamber pumping

Turbo pumping stage, chamber door differentially pumped by dry foreline pump

Load lock chamber

Base pressure

< 5 * 10-8 mbar

Pump down time

< 0.5 hours to < 10-6 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

Sputtering chamber

Sample size

diameter max. 4″ substrate

Motion axes

2 motorized axes (manipulator arm rotation and z tranlsation of the sample stage)

Temperatures

Room temperature (not stabilized) up to 600°C at sample

Special features

Sample bias (RF, DC or pulsed DC) is possible

E-beam chamber

Sample size

diameter max. 4″ substrate

Motion axes

1 manual axis (manipulator stage tilting)

Special features

3 sample holder clamping positions (one above each deposition source)

Sample preparation features

Sputtering chamber

Oxydation / Nitration /

Plasma treatment

max. 5 * 10-4 mbar partly ionised gas mixture (using a griddless ion gun)

Gas mixture variable from pure argon up to pure oxygen or nitrogen

Ion beam etching /

sample precleaning

Variable ion source to sample distance

Wide range variable ion energy and ion beam current

Load lock chamber

Thermal treatment

Room temperature up to about 300°C at sample (no temperature regulation)