P457 – Mirror Unit VNIIOFI KSRS

Application

Mirror unit (M1) for soft X-ray synchrotron radiation

Year of delivery

2017

Installation site

VNIIOFI beamline at the synchrotron radiation source KSRS, Russia

This mirror unit for the VNIIOFI beamline at the KSRS features a Cartesian constant-strut-length hexapod mechanism to realize the required degrees of freedom. The cartesian design allows for intuitive manual mirror alignment.

Design Features

-

Cartesian constant-strut-length hexapod mechanism.

- Spectral range: 2.5 – 1200 eV.

- Optical elements: one collimating mirror.

- Manual alignment of the mirror in six degrees of freedom.

-

Active side water cooling of the mirror.

- Electrode in front of mirror surface.

- Temperature sensors at mirror holder.

- Four water cooled, motorized and electrically isolated Tungsten blades at the entrance flange.

- Temperature sensors at the aperture blades.

- Permanently installed bakeout provisions.

- Adjustable support structure.

Performance Features

- Cartesian constant-strut-length hexapod mechanism.

- Intuitive manual mirror alignment due to cartesian design.

- High step resolution (actuated manually).

- High stability for all degrees of freedom.

- Minimized mounting induced deformations.

Outer Dimensions

Technical specifications and performance values

General

Vacuum chamber

Chamber type

stadium shaped footprint

Main flanges

at the top

Material

1.4404 (C < 0.02%)

Base pressure

10-10 mbar range

Optical design parameters

Beam height

1940 mm

Number of mirrors

1

Surface shape

elliptical-toroidal

Mirror dimensions

800 x 50 x 60 mm3

Mirror mechanics

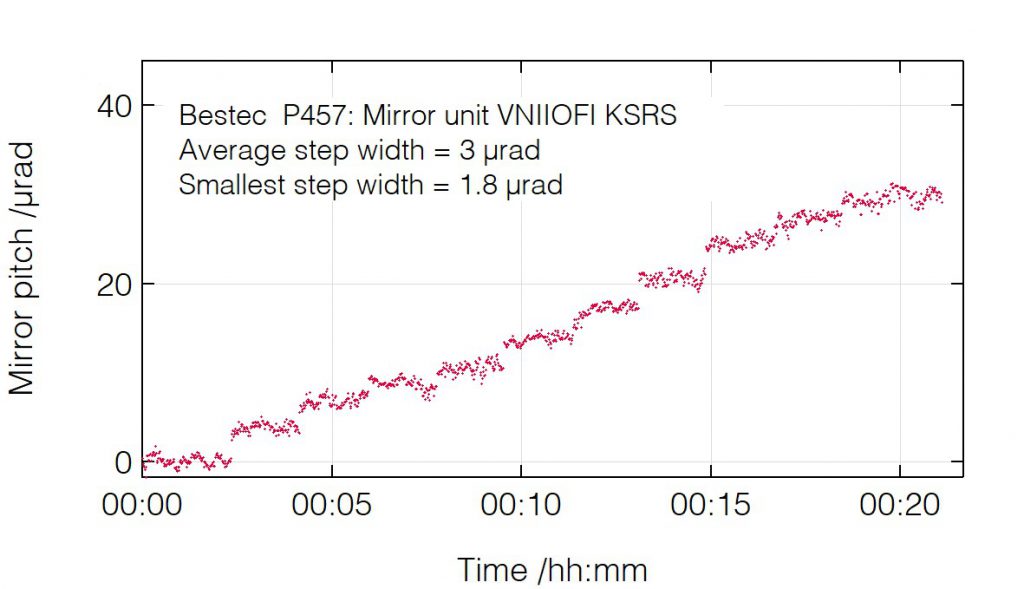

Pitch rotation (Ry) – manual

Range

± 1°

(relative to mirror default position)

Gear ratio

0.063° /turn

Average step width

3 µrad

Minimum step width

1.8 µrad

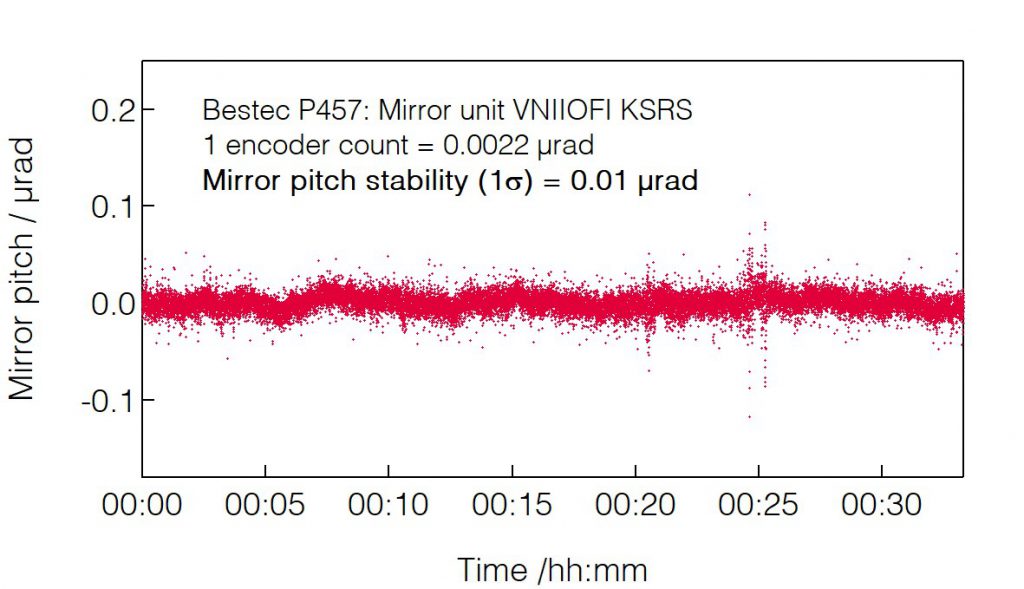

Long-term stability

(ca. 30 minutes)

< 0.01 µrad

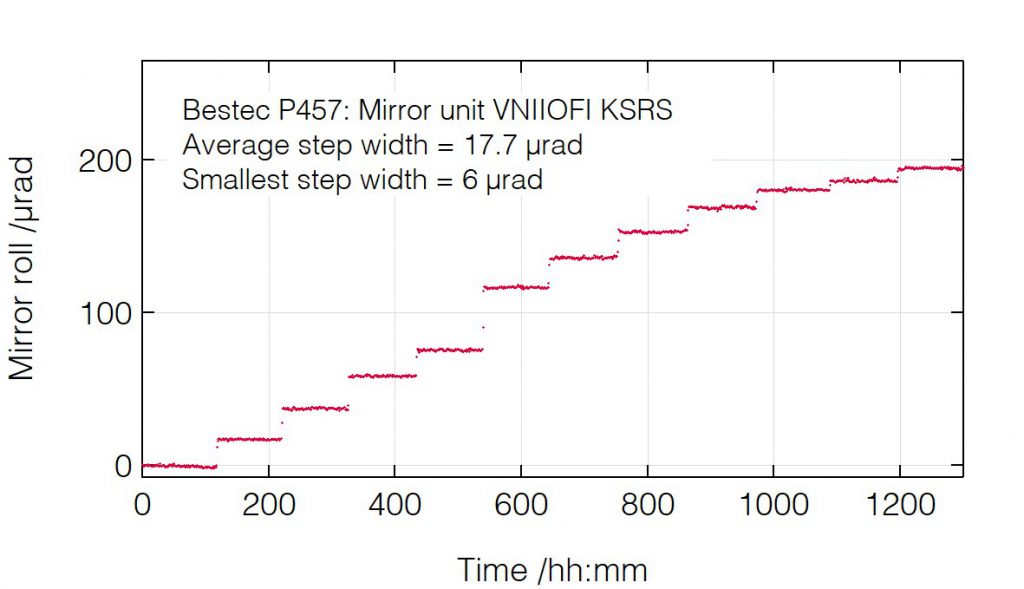

Roll rotation (Rz) – manual

Range

± 1°

(relative to mirror default position)

Gear ratio

0.3° /turn

Average step width

17.7 µrad

Minimum step width

6 µrad

Yaw rotation (Rx) – manual

Range

± 1°

(relative to mirror default position)

Gear ratio

0.063° /turn

Mirror translation (Tx) – manual

Range

± 1 mm

(relative to mirror default position)

Gear ratio

0.5 mm /turn

Mirror translation (Ty) – manual

Range

± 1 mm

(relative to mirror default position)

Gear ratio

0.5 mm /turn

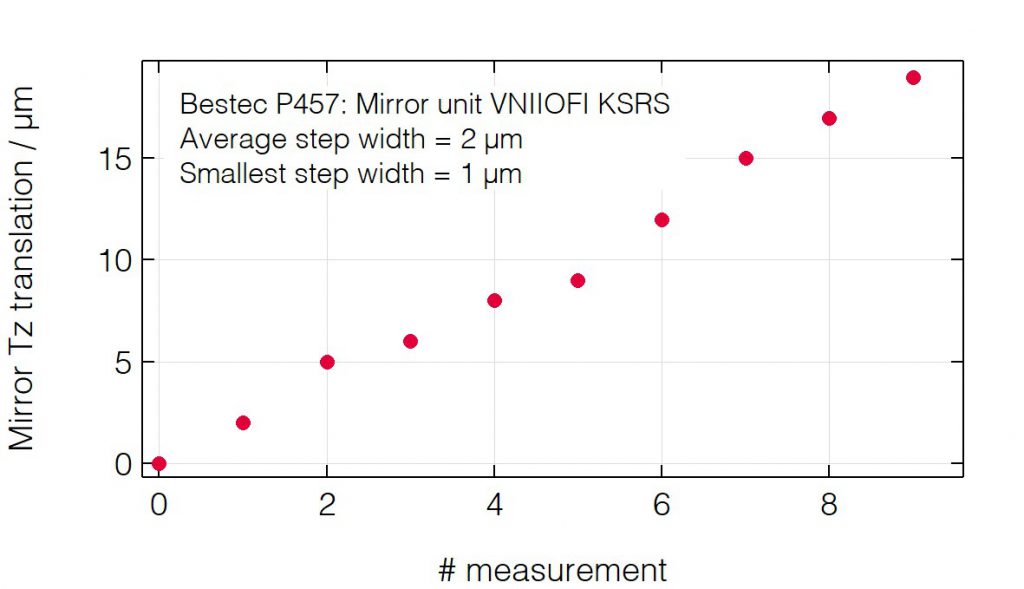

Mirror translation (Tz) – manual

Range

± 1 mm

(relative to mirror default position)

Gear ratio

0.5 mm /turn

Average step width

2 µm

Minimum step width

1 µm

Aperture unit

Blades

Material

Tungsten

Absorber material

OFHC

Range

± 25 mm

Resolution (design value)

0.006 µm /motor fine step

(1/16, recommended)

0.05 µm /encoder count