P407 – Mirror Unit M3_hard EMIL BESSY

Application

Mirror unit (M3) for hard X-ray synchrotron radiation

Year of delivery

2015

Installation site

EMIL hard X-ray beamline at BESSY, Helmholtz-Zentrum Berlin, Germany

This hard X-ray split mirror unit is part of the combined hard and soft X-ray EMIL beamlines at BESSY. It features an optimized design of the constant-strut-length hexapod mechanism used for the first Bestec hexapod (see project P377). The mirror splitting is realized by a vertical movement. The vacuum chamber accomodates not only the actual beam but also the passing soft X-ray and pink beams of the neighbouring branches.

Design Features

-

Constant-strut-length hexapod mechanism.

- Six degrees of freedom and selectable rotation center.

- Spectral range: 2 – 10 keV.

- Optical elements: two focusing mirrors (for soft and for hard X-ray radiation).

- Electrodes at mirrors surfaces for carbon contamination prevention.

-

Provisions for RF oxygen plasma cleaning of the optical surfaces.

- Four motorized OFHC aperture blades at the entrance flange.

- Permanently installed bakeout provisions.

- Adjustable support structure.

Performance Features

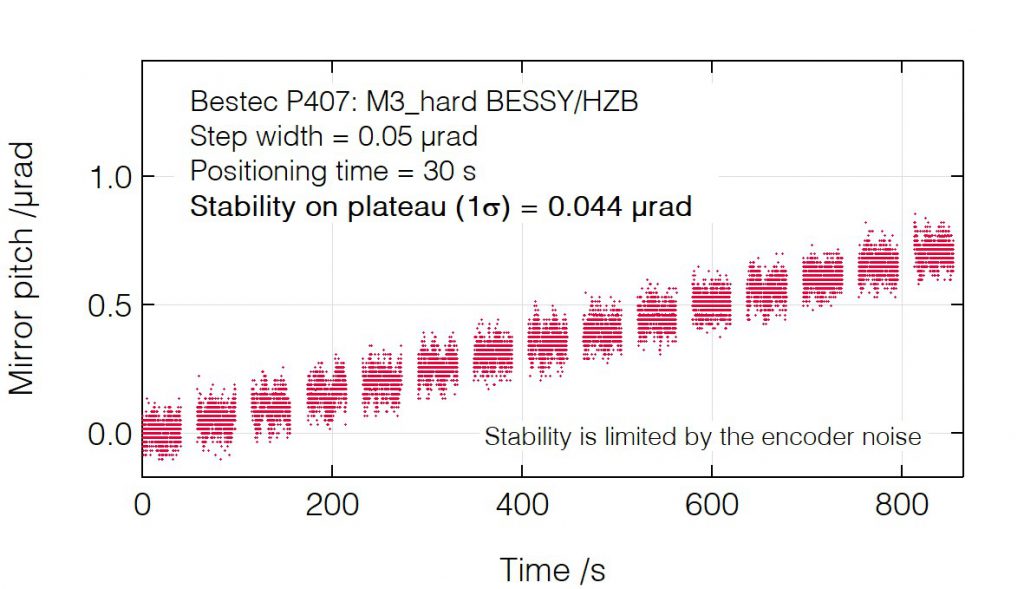

- High positioning resolution (minimum incremental motion).

- High stability and repeatability for all degrees of freedom.

- Minimized mounting induced deformations.

Outer Dimensions

Technical specifications and performance values

General

Vacuum chamber

Chamber type

cylindrical, vertical axis

Main flanges

at the top

Material

1.4404 (C < 0.02%)

Base pressure

10-10 mbar range

Optical design parameters

Beam height

1420 mm

Number of mirrors

2

Surface shape

cylindrical

Mirror dimensions

520 x 40(25) x 40(8) mm3

(T-Profile)

Actuator drives for hexapod axes

Resolution (design value)

0.004 µm /motor fine step

(1/128, recommended)

0.005 µm /encoder count

Mirror mechanics

Pitch rotation

Range

-10 mrad to +12 mrad

Resolution (measured value)

0.05 µrad

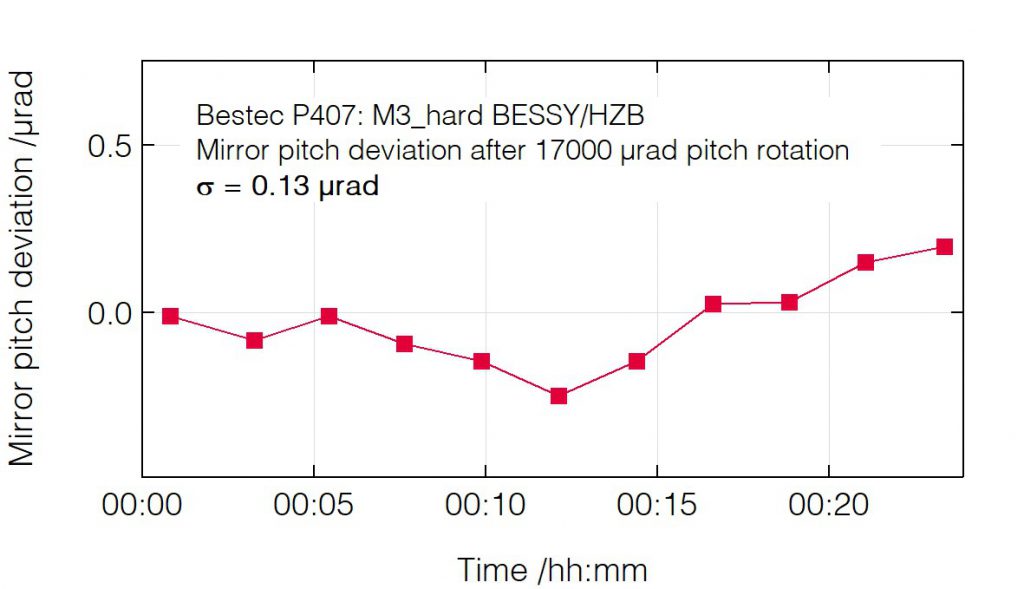

Repeatability

0.13 µrad (pitch)

0.22 µrad (roll)

Roll rotation

Range

± 10 mrad

Resolution

0.05 µrad

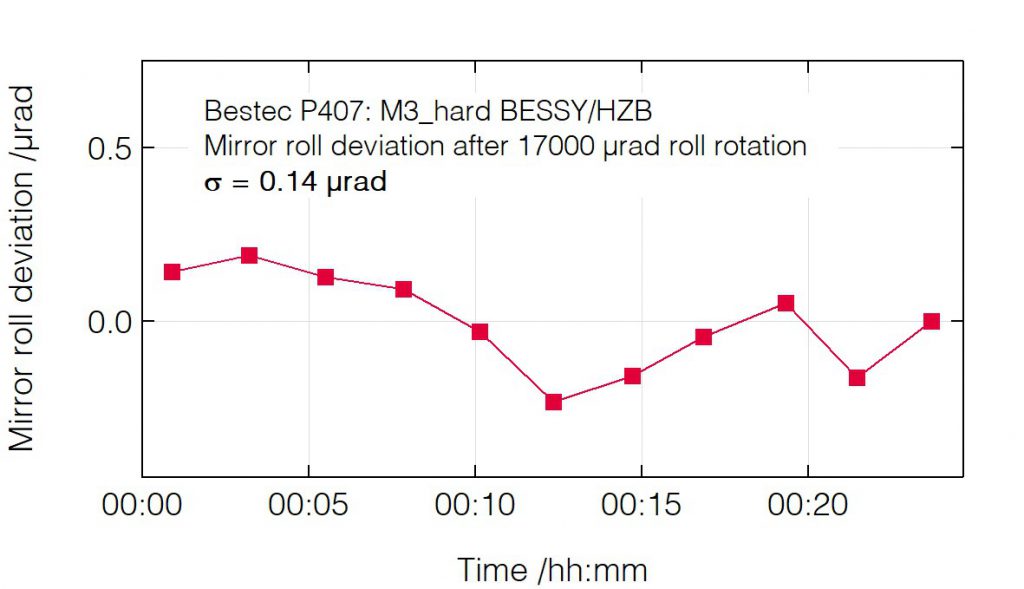

Repeatability

0.07 µrad (pitch)

0.14 µrad (roll)

Yaw rotation

Range

± 8 mrad

Resolution

0.05 µrad

Vertical translation (switch)

Range

± 15 mm

Horizontal translation

Range

± 5 mm

Aperture unit

Blades

Material

OFHC

Stroke

25 mm, 50 mm

Resolution (design value)

10 µm /motor step

(full step at actuator)

0.11 µm /motor fine step at blade

(1/64, recommended)