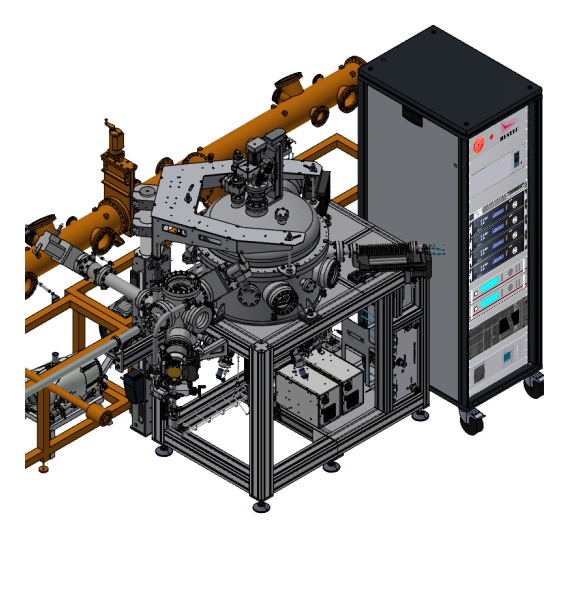

P503 – 2″ UHV sputter deposition TU Darmstadt

Application

UHV sputter deposition system for thin film and multilayer deposition at 2″ substrates

Year of delivery

2023

Installation site

TU Darmstadt, Germany

Design Features

- UHV magnetron sputter deposition system with combination of confocal and face to face sputter up configurations.

- Up to eight 2″ magnetrons in confocal configuration and up to one 3″ magnetrons in face to face configuration.

- 2″ magnetrons with pneumatic in situ tilting.

- 3″ magnetron with pneumatic in situ translation

- All 2″ magnetrons with easy changeable magnetic system for use with ferromagentic or non-ferromagnetic target materials.

- Low pressure and low power sputtering possible.

- Fully motorized 2 axes sample manipulator with integrated pneumatic sample shutter and maximal sample temperature well above 700°C.

- Integrated bake out system.

- Load lock chamber with storage.

Special Features

- Very small sample to target distance possible (less than 20mm for 3″ magnetrons).

- System is prepared to be added to a cluster tool via second transfer port at loadlock chamber.

- Different sample sizes from 2″ wafer down to 10mm x 10mm samples can be handled (using different kind of sample adapters).

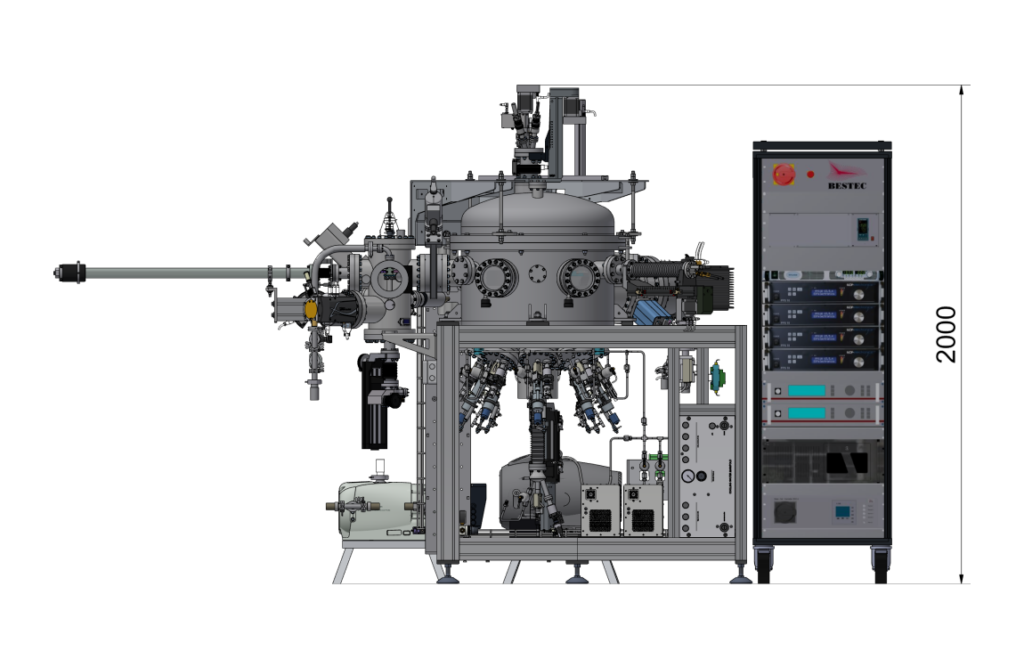

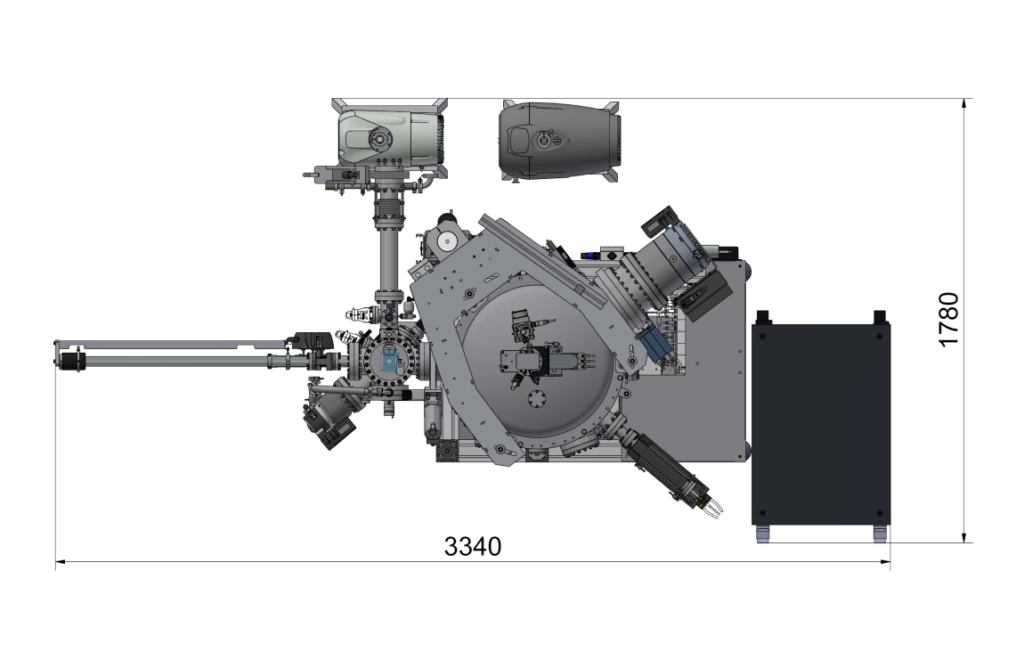

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

600 mm diameter, about 700 mm height

Material

stainless steel

Load lock chamber

Size

200 mm diameter, about 350 mm height

Material

stainless steel

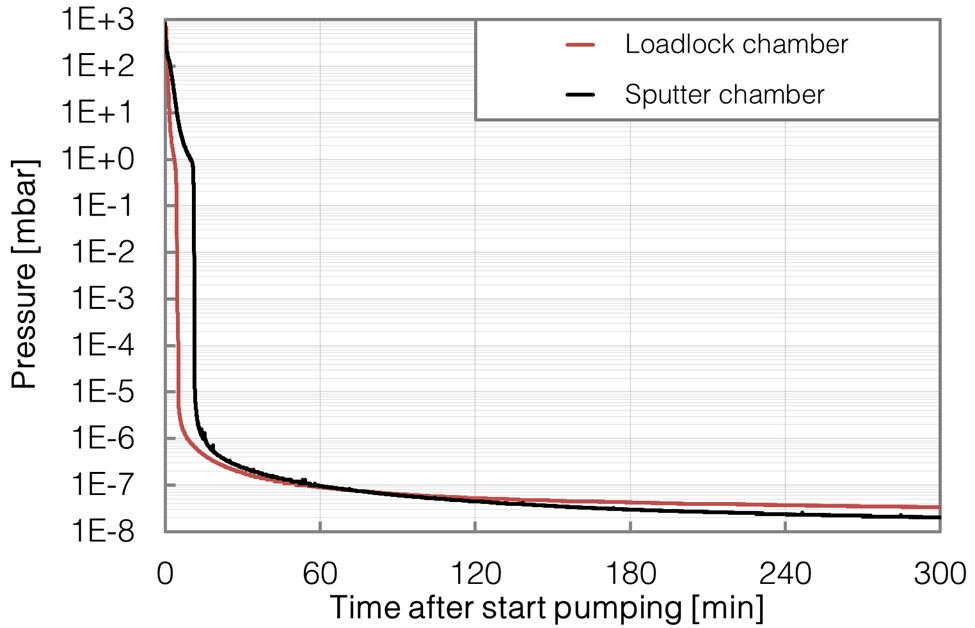

Vacuum

Sputtering chamber

Base pressure

< 1 * 10-8 mbar

Pump down time

1 hour to < 10-7 mbar

Chamber pumping

Turbo pumping stage, chamber lid differentially pumped by dry foreline pump

Bake out

< 150°C

Load lock chamber

Base pressure

< 10-7 mbar

Pump down time

1 hour to < 10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

Sputtering chamber

Sample size

diameter max. 2″ substrate

Motion axes

2 motorized axes (manipulator z tranlsation and (continous) sample stage rotation)

Pneumatic sample shutter (part of the manipulator head)

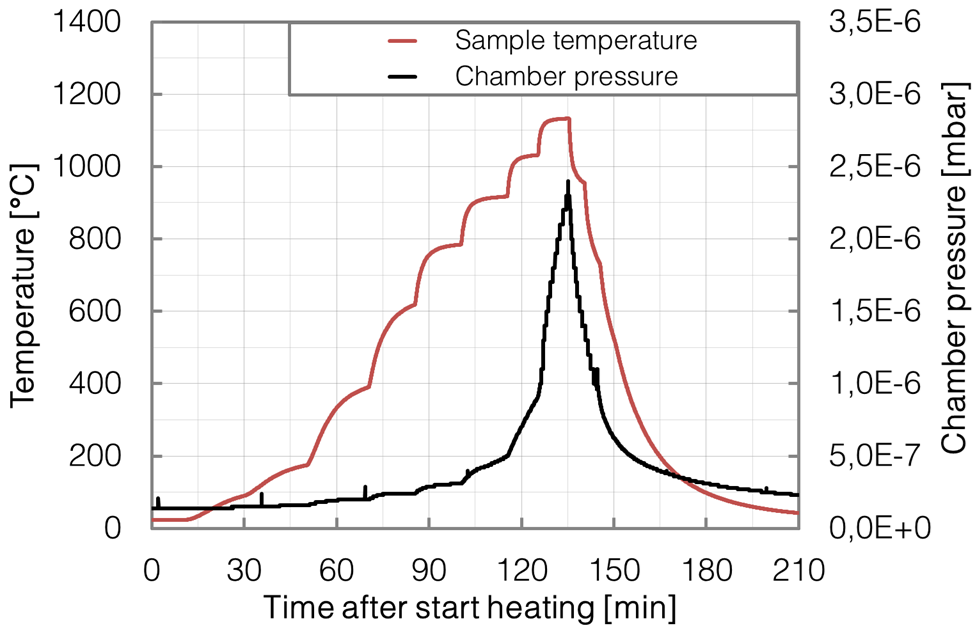

Temperatures

Room temperature (not stabilized) up to 1000°C at sample (short time heating) / > 700°C at sample (long time heating)

Load lock chamber

(Sample storage)

Storage size

6 sample holders

Sample size

diameter max. 2″ substrate

Motion axes

2 manual axes (rotation, z tranlsation)

Rotation axis equipped with an air side scale plate for easy and fast sample loading via access door or one out of two transfer rods