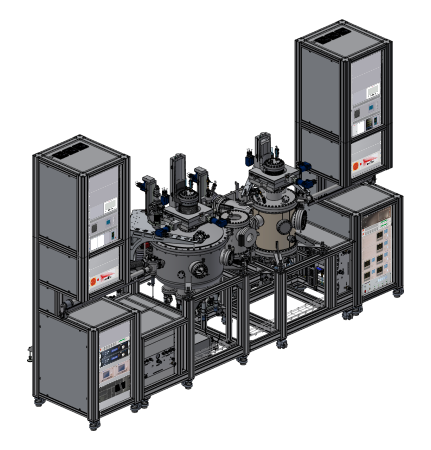

P479 – 2″ UHV Multitech. deposition system Uni Bielefeld

Application

Multi chamber system as combination of UHV MBE system & UHV sputter deposition system for thin film and multilayer deposition at 2″ substrates

Year of delivery

2021

Installation site

University Bielefeld, Germany

Design Features

- Multitechnique deposition system consting a UHV magnetron sputter deposition system and a UHV MBE system connected to a load lock chamber.

- UHV magnetron sputter deposition system with combination of confocal and face to face sputter up configurations.

- Up to six 2″ magnetrons in confocal or face to face configuration and one 3″ magnetrons in confocal configuration.

- Three 2″ magnetrons mounted at a rotating cluster flange in face to face configuration.

- Three 2″ magnetrons and the 3″ magnetron with pneumatic in situ tilting.

- All magnetrons with easy changeable magnetic system for use with ferromagentic or non-ferromagnetic target materials.

- DC switching unit and RF switching unit (two sources connected to one generator).

- Fully motorized 3 axes sample manipulator with integrated sample shutter and maximal sample temperature well above 800°C.

- Up to six 2″ magnetrons in confocal or face to face configuration and one 3″ magnetrons in confocal configuration.

- UHV MBE system with combination of up to seven effusion cells in confocal configuration and optional e-beam source in face to face configuration.

- Hot filament effusion cells as well as dual filament effusion cells possible.

- Fully motorized 3 axes sample manipulator with integrated sample shutter and maximal sample temperature well above 800°C.

- Integrated bake out system.

- Load lock chamber with storage and lamp heating option.

Special Features

- Two types of manipulator head can be used

- Magnet head (supplied by costumer)

- Sample heating head

- Load lock chamber is prepared for adding a third deposition chamber.

- Handling of samples with electric contacts for in situ thin film diagnostic.

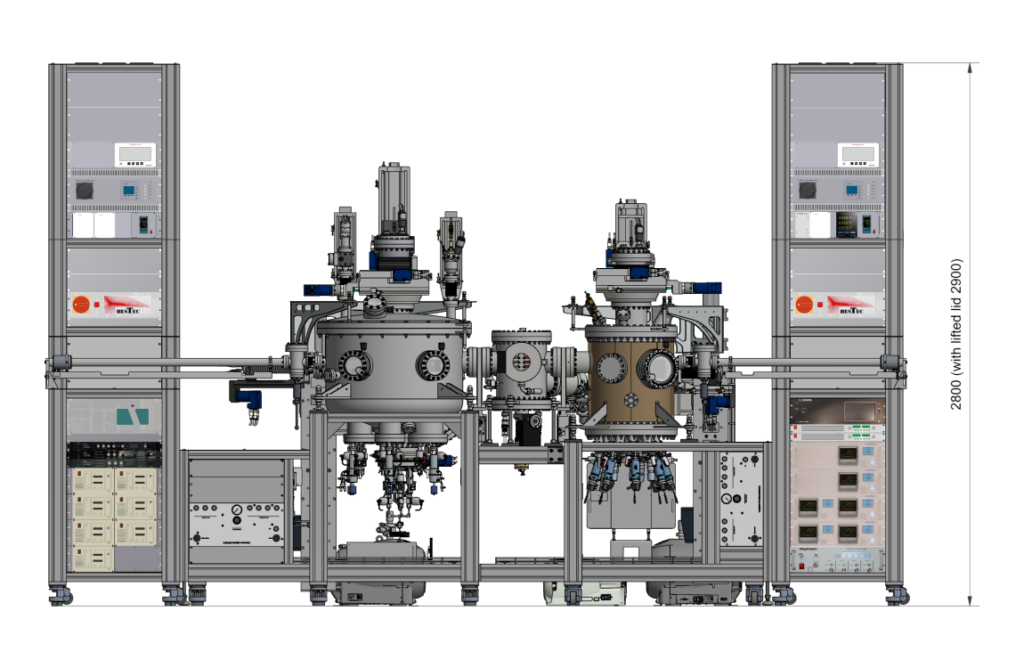

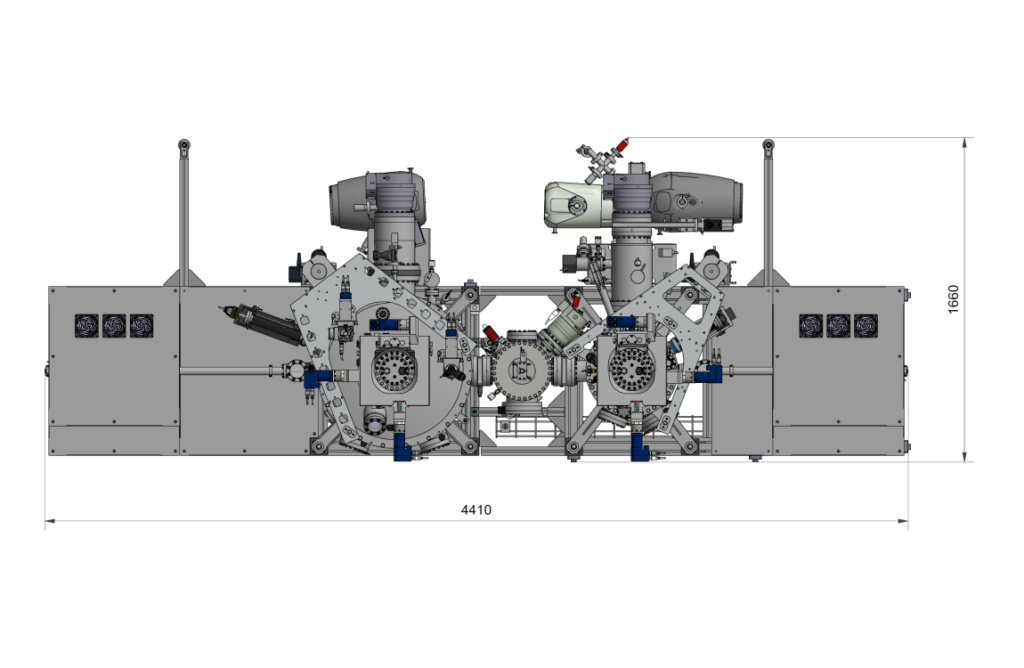

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

700 mm diameter, about 700 mm height

Material

stainless steel

MBE chamber

Size

400 mm diameter (340 mm cryo shroud inner diameter), about 730 mm height

Material

stainless steel

Load lock chamber

Size

200 mm diameter, about 400 mm height

Material

stainless steel

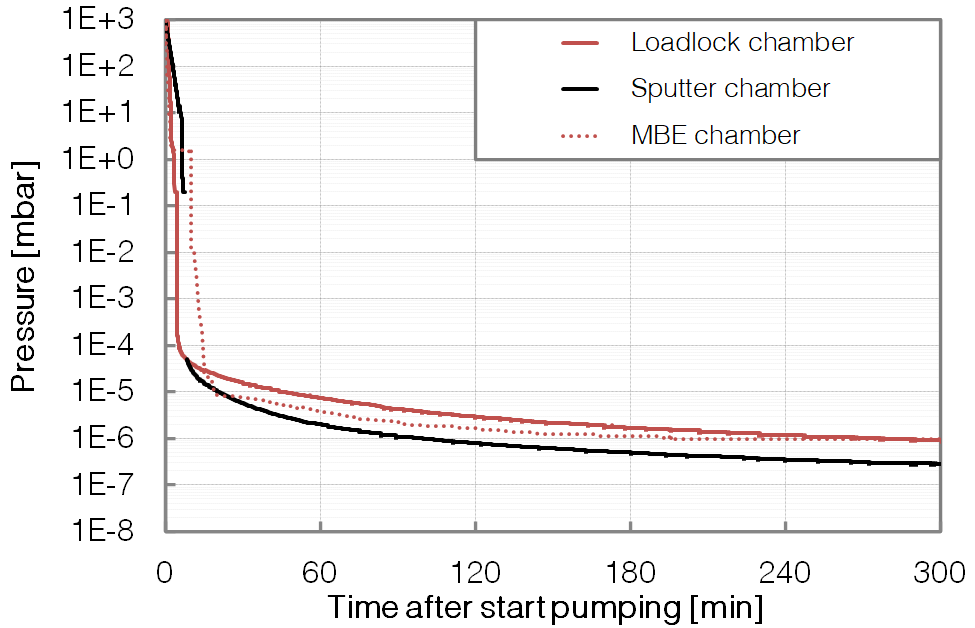

Vacuum

Sputtering chamber

Base pressure

< 3 *10-9 mbar

Pump down time

will be added soon

Chamber pumping

Turbo pumping stage, chamber lid and rotating magnetron source cluster differentially pumped by dry foreline pump

Bake out

< 150°C

MBE chamber

Base pressure

< 3 *10-10 mbar

Pump down time

will be added soon

Chamber pumping

Combined turbo pump, ion getter pump and titanium sublimation pumping stage with dry foreline pump

Bake out

< 200°C

Load lock chamber

Base pressure

< 10-8 mbar

Pump down time

will be added soon

Chamber pumping

Turbo pumping stage, chamber door differentially pumped by dry foreline pump

Manipulator features

Sputtering chamber

Sample size

diameter max. 2″ substrate

Motion axes

3 motorized axes (manipulator x, y, and z tranlsation)

Pneumatic sample shutter with motorized z-translation stage (shutter to sampe distance can be constant while moving the manipulator head)

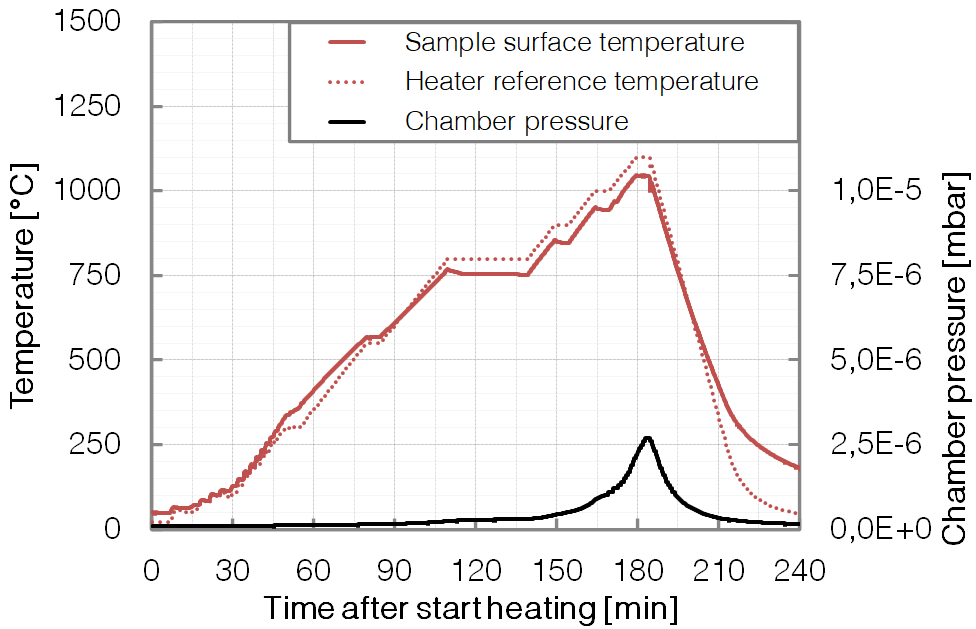

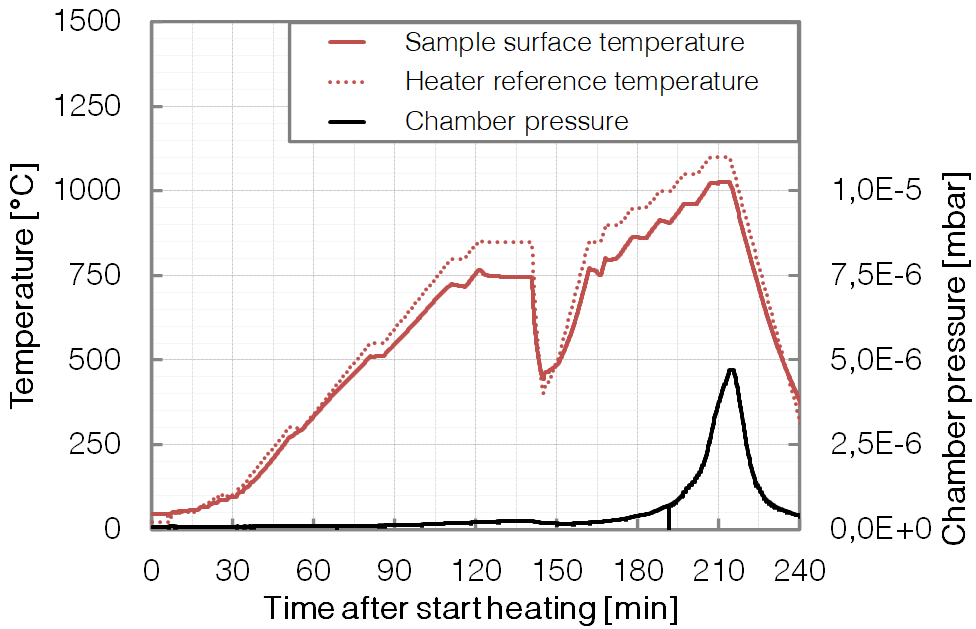

Temperatures

Room temperature (not stabilized) up to > 950°C at sample

Special features

DC Bias possible

Use of samples with integrated electrical contacts possible

MBE chamber

Sample size

diameter max. 2″ substrate

Motion axes

3 motorized axes (manipulator x, y, and z tranlsation)

Pneumatic linear motion sample shutter mounted at fixed height to chamber wall

Temperatures

Room temperature (not stabilized) up to > 950°C at sample

Special features

DC Bias possible

Use of samples with integrated electrical contacts possible

Load lock chamber

(Sample storage)

Storage size

5 sample holders

Sample size

diameter max. 2″ substrate

Motion axes

2 manual axes (rotation, z tranlsation)

Rotation axis equipped with an air side idexer plate for easy and fast sample loading via access door or transfer rod

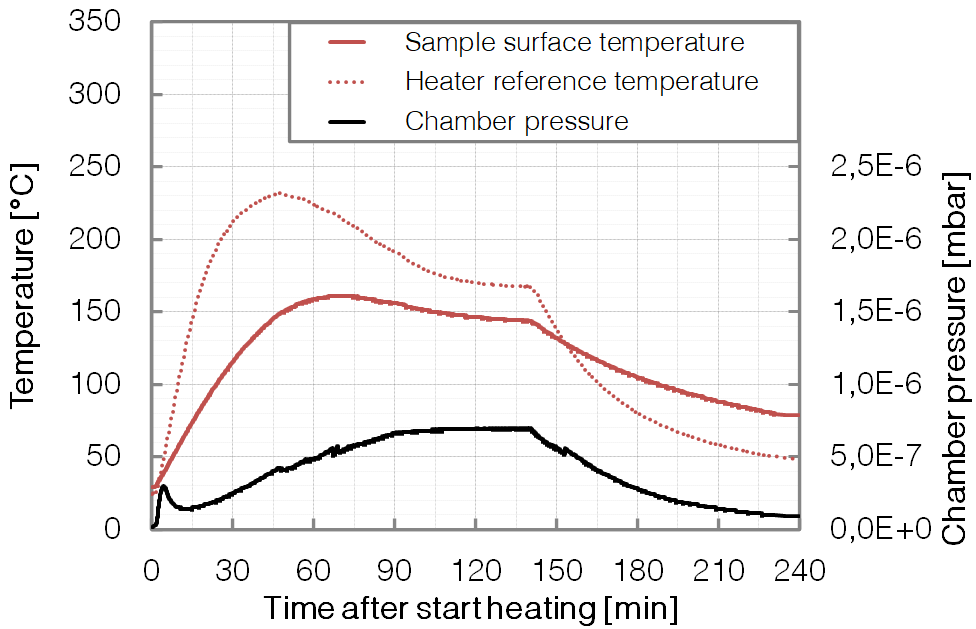

Sample preparation features

Load lock chamber

(Sample storage)

Thermal treatment

Room temperature up to about 200°C at sample (no temperature regulation)