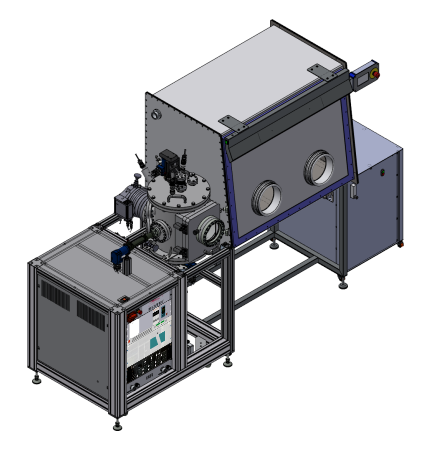

P476 – 1″ HV Ion beam sputter deposition system MLU

Application

HV ion beam sputter deposition system for thin film and multilayer deposition at 1″ substrates

Year of delivery

2020

Installation site

MLU, Halle (Saale), Germany

Design Features

- HV ion beam sputter deposition system.

- One focused gridded DC ion source oriented towards a target manipulator with four 2″ targets.

- Fully motorized 3 axes target manipulator (manipulator z translation, manipulator rotation & (continous) target rotation).

- Fully motorized 2 axes sample manipulator with intergated shutter & mask positioning and maximal sample temperature well above 800°C.

- Big front door for sample exchange and service tasks.

- Side port with door for glove box integration.

Special Features

- Up to 3 masks can be mouted to the sample stage at the same time to be exchanged automatically during a deposition process.

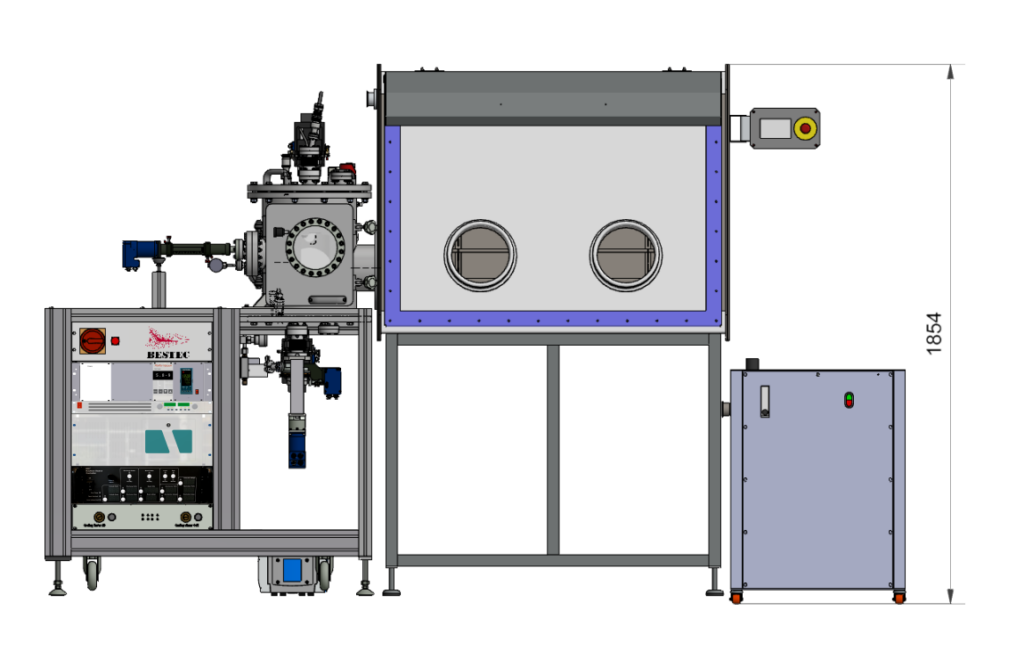

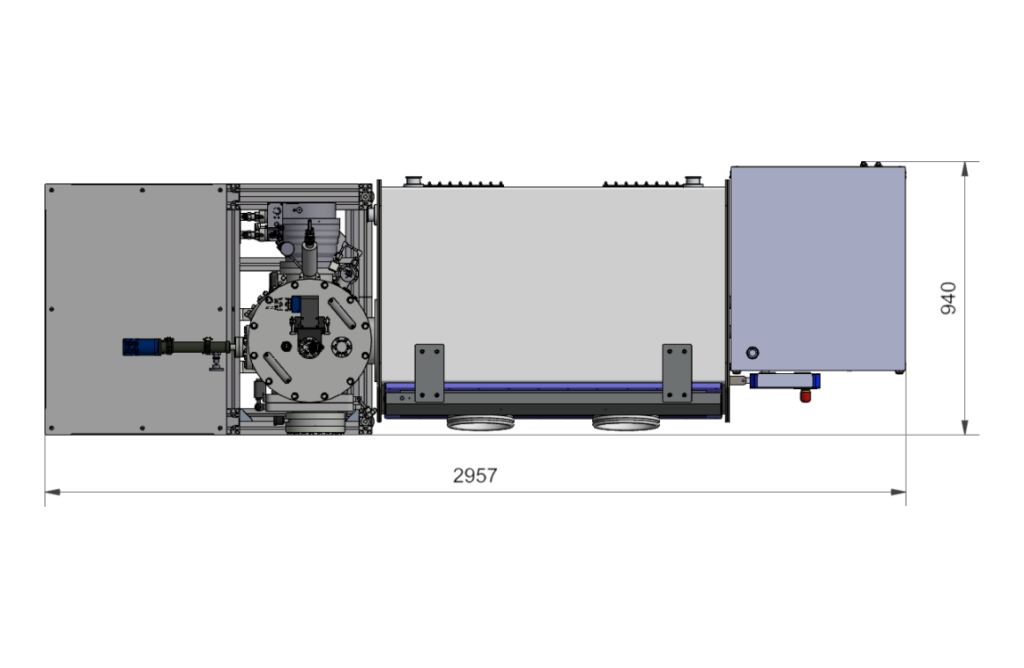

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

320 mm diameter, about 430 mm height

Material

stainless steel

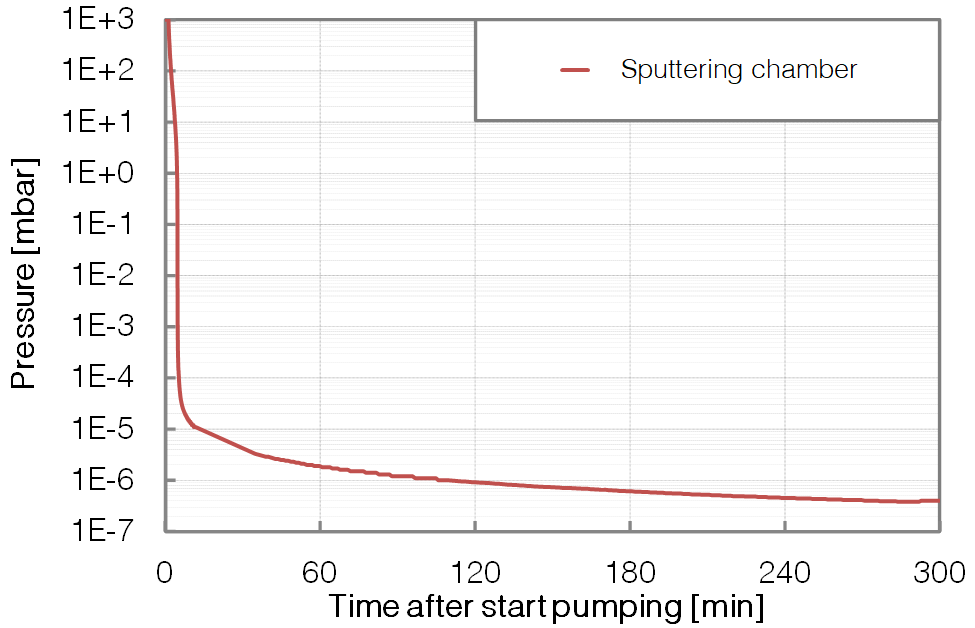

Vacuum

Sputtering chamber

Base pressure

< 10-7 mbar

Pump down time

4 hours to < 5 * 10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

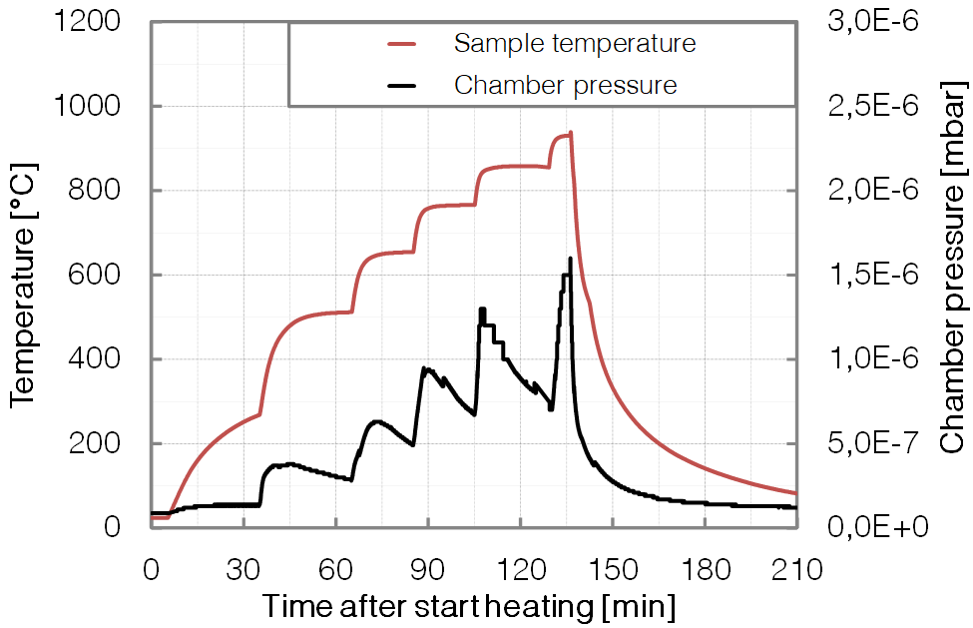

Manipulator features

Sputtering chamber

Sample size

diameter max. 1″ substrate

Motion axes

2 motorized axes (manipulator z translation and mask (exchange) translation)

Temperatures

Room temperature (not stabilized) up to 800°C at sample