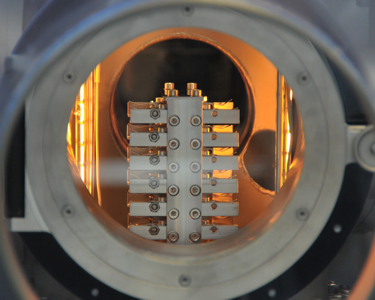

Sample preparation equipment

Different kind of sample preparation requipments are widely used in UHV deposition systems. Depending on the specifications of the deposition process or the resulting thin film this can be mild plasma etching of oxids or organic layers on the sample surface. Additionally controlled oxidation, nitration or sample heating can be used for sample preparation too. Bestec provides related equipment for all these preparation techniques as part of a Bestec deposition system.

Typical design parameters

- Mild ion beam etching (plasma etching), plasma oxidation or plasma nitration using a griddless endhole ion source.

- Thermal treatment up to about 300°C using lamp heater assemblies (power controlled) in LoadLock chamber.

- Thermal treatment up to about 900°C using radiation heater assembly (power or temperature controlled) as part of sample manipulator in the deposition chamber.

- Full software control possible via integrated serial communication port.

Options

- Integration of pressure interlock possible.

- Integration of temperature controll for LoadLock heating systems possible.

- Integration of static oxidation or nitration procedures instead of plasma oxidation or nitration possible.