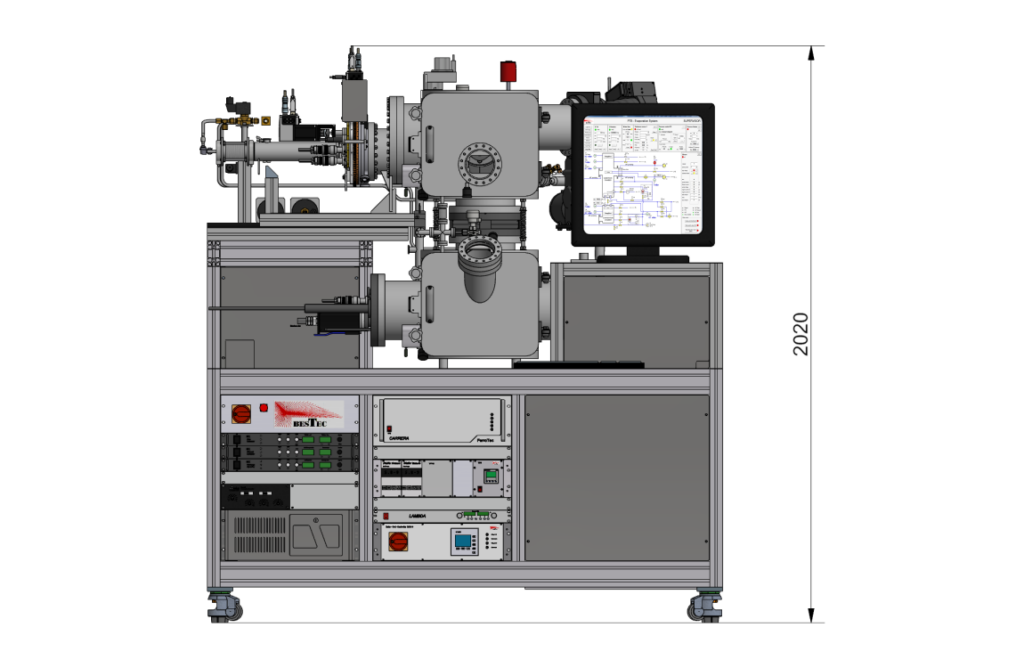

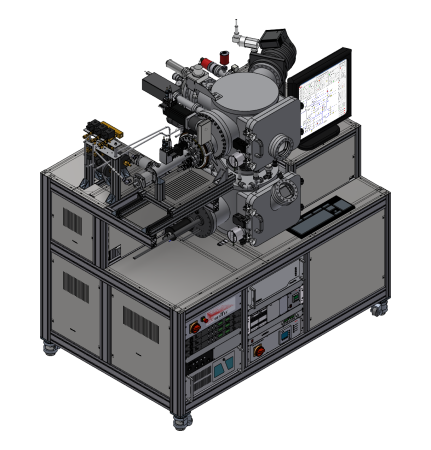

P331 – 3″ UHV e-beam deposition PTB

Application

UHV e-beam deposition system for thin film and multilayer deposition at 3″ substrates

Year of delivery

2012

Installation site

PTB, Braunschweig, Germany

Design Features

- UHV e-beam deposition system with ion source sample treatment and preparation.

- Linear multi pocket e-beam source.

- Manual pocket exchange.

- Thickness controller incl. software rate regulation and end point detection.

- Fully motorized 2 axes sample manipulator with integrated sample tempering between -150°C and +100°C.

- Ion source for sample precleaning, mild etching and plasma treatment.

- Residual gas analysis installed.

- Integrated bake out system.

Special Features

- Two chamber design to enable fast sample eschange without contamination of the evaporation material.

- Sample chamber with manipulator on top.

- E-Beam chamber below.

- Both chambers seperated by gate valve with deposition protection shield.

- Cryo shroud in both chambers leading to low and constant deposition pressure conditions.

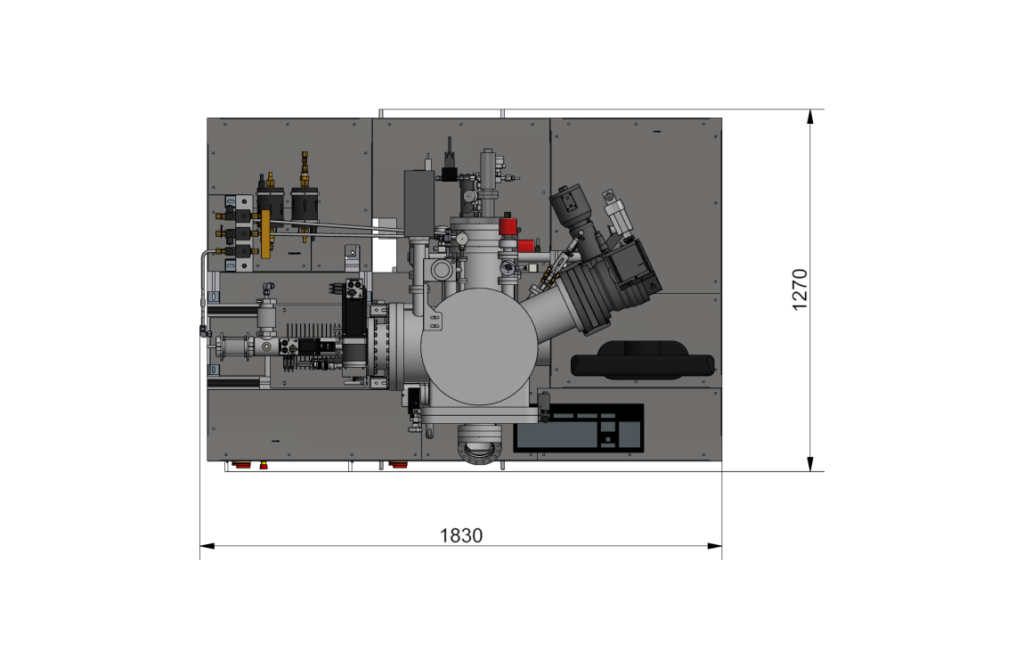

Outer Dimensions

Technical specifications and performance values

General

Sample chamber

Size

400 mm diameter, about 350 mm height

Material

stainless steel

E-Beam chamber

Size

400 mm diameter, about 350 mm height

Material

stainless steel

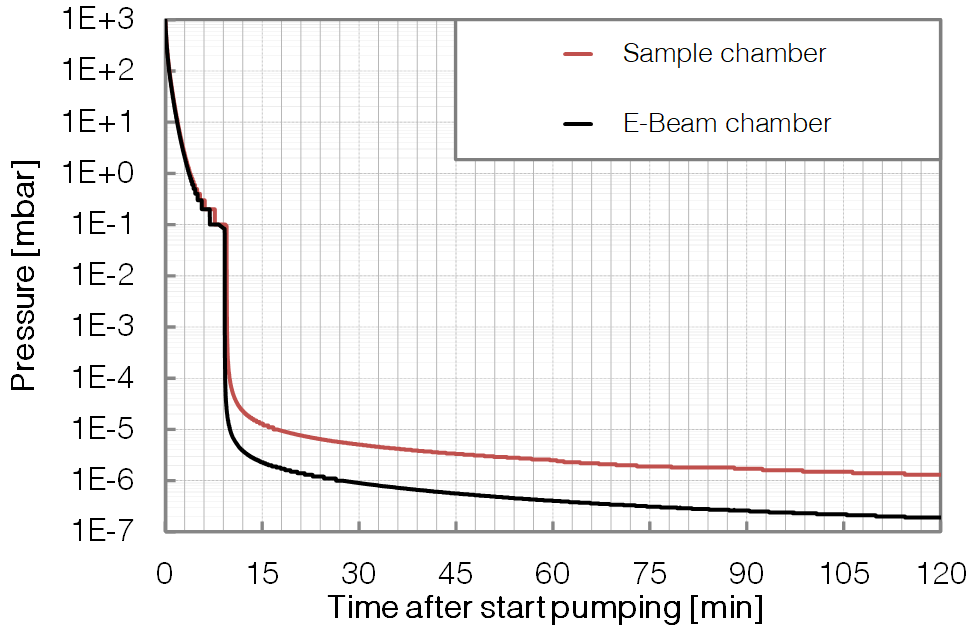

Vacuum

Sample chamber

Base pressure

< 5 * 10-9 mbar

Pump down time

1 hour to < 10-6 mbar

Chamber pumping

Turbo pumping stage, chamber door differentially pumped by dry foreline pump

Bake out

< 150°C

E-Beam chamber

Base pressure

< 5 * 10-9 mbar

Pump down time

1 hour to < 10-6 mbar

Chamber pumping

Cryo pumping stage, chamber door differentially pumped by dry foreline pump

Bake out

< 150°C

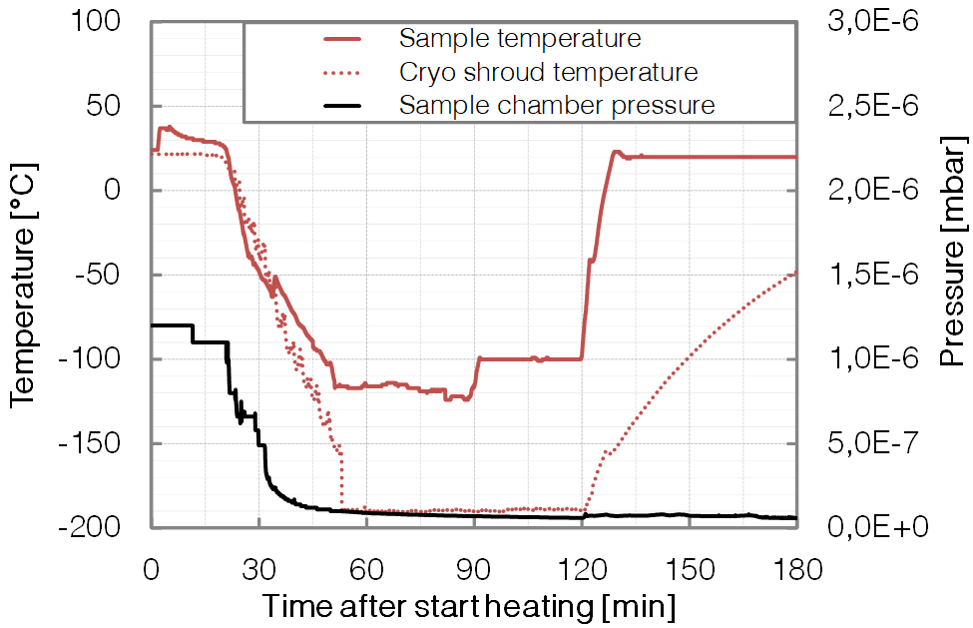

Manipulator features

Sample chamber

Sample size

diameter max. 3″ substrate

Motion axes

2 motorized axes (manipulator tilting and (continous) sample stage rotation)

Temperatures

-150°C (not regulated) up to +100°C at sample

Sample preparation features

Sample chamber

Plasma treatment

Up to 5 * 10-4 mbar mbar partly ionised argon gas (using a griddless ion gun)

Ion beam etching /

sample precleaning

Wide range variation of ion source to sample distance

Wide range variation of ion energy and ion beam current

Dynamic oxydation pressure (regulation)

10-5 mbar up to 10 mbar (via upstream pressure regulation)